GROW WITH US

Streamline your workflows and minimize manual disorganization. Optimize manufacturing with our cutting-edge technologies and automation solutions.

Automatic Length Hemming

The Automatic Length Hemming Machine ensures precise and efficient finishing of fabric edges. It accurately cuts the fabric to a desired length and removes any excess waste, minimizing material loss. It then proceeds to fold the fabric edge thrice, creating a durable and neat hem. Finally, the machine stitches the folds, ensuring a strong and consistent finish.

Textile manufacturers can benefit from high-precision hemming services as it can improve product quality, reduce labor costs, and increase production efficiency.

Beam Barrel

Beam Barrels are crucial for the efficient loading and transportation of thread, ensuring a smooth transfer to our production machines. These barrels are designed to hold large quantities of thread for maintaining its tension, so it doesn’t tangle during movement. With this, our machines receive a consistent and uninterrupted supply of thread, minimizing downtime and maximizing productivity.

Our Beam Barrels are designed to optimize thread transport, reduce material waste and improve production flow.

Inspection Machine

The Fabric Inspection Machine is essential for ensuring the quality of our raw, unfinished textiles. This machine precisely examines Greige fabric for defects such as yarn imperfections, weaving flaws, and contamination. It utilizes advanced optical systems and lighting to detect every minor inconsistency.

Fabric inspection saves manufacturers crucial time and resources as it allows us to identify issues early in the production process, lowering waste and ensuring that only high-quality greige fabric moves forward.

Roll Unwinder Machine (Fabric Cloth)

The Roll Unwinder Machine provides a consistent feed of fabric for our weaving equipment. It maintains the fabric’s tension, preventing tears and wrinkles, which is vital for the efficiency of our Water Jet Loom.

With the Roll Unwinder Machine, consistent fabric feeding system ensures a smooth and efficient fabric supply for every Water Jet Loom.

Roll Unwinder Machine (Fabric Cloth)

Producing high-quality microfiber fabric from thread is essential for any textile manufacturer. Our Water Jet Loom utilizes high-pressure jets of water to weave intricate patterns, resulting in a tightly woven, fine microfiber material. This process allows us to create fabrics with exceptional softness, durability, and uniformity.

By leveraging the advanced capabilities of the Water Jet Loom, we create premium microfiber materials. and meet the growing demand for fine, high-performance textiles.

Bulging Removal Machine

The Bulging Removal Machine maintains the uniformity and quality of our metallic products. It effectively eliminates bulges and imperfections from metal surfaces, resulting in a smooth and consistent finish. The machine uses precise mechanical procedures to remove unwanted protrusions, making sure that all our products meet strict quality standards. This process enhances the aesthetic appeal and structural integrity of our metal components.

By utilizing this machine, we achieve a higher level of product consistency, reduce defects and improve its overall finish.

CNC Laser Cutting Machine

Creating intricate metal shapes with precision is vital. Our CNC Laser Cutting Machine consists of a powerful laser beam that’s controlled by a computer program. It’s used to cut metal sheets into various custom designs accurately and consistently. The machine's ability to follow precise computer-generated patterns allows us to achieve very tight tolerances.

Being able to produce complex metal shapes with exact specifications doesn’t have to require ample manufacturing time. The CNC Laser Cutting Machine can do all that and more while guaranteeing quality with precision.

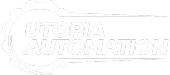

CNC Machine Auto

The CNC Machine Auto is a multi-faceted piece of technology that fabricates metallic parts through the integration of Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) programs with complete automation. By translating digital designs into physical components, it ensures consistent quality and tight tolerances.

A fully automated CNC Machine produces metallic parts that meet exact specifications. It also significantly reduces production time, minimizes errors, and delivers superior components through automation.

Drill Machine

Our Drill Machine is programmed to accommodate complex drilling patterns with accuracy. Its primary function is creating holes in a variety of materials. From simple to complex drilling patterns, this machine assists us in maintaining tight tolerances while providing the exactness and reliability we require.

Consistency and accuracy are two fundamental drivers for a Drill Machine, and our machine offers both to promote high-quality production.

Hacksaw Machine

The Hacksaw Machine specifically cuts metal materials based on the provided dimensions, preparing them for further processing. It maintains a tight tolerance and is robustly constructed to handle several types of metal.

Metal cutting is all about precision and our Hacksaw Machine offers state-of-the-art metal cutting.

Induction Melting Furnace

Induction Melting Furnace completes our metal forming processes by using electromagnetic induction to efficiently melt metal, allowing us to create ingots. The temperature control and rapid melting capabilities of this furnace ensure homogeneous melts.

Metalworking through our Induction Melting Furnace ensures that we melt and form metal to their specific requirements for utilizing it in our various production needs.

Manual Bending Fixer

The Manual Bending Fixer is a hand-operated system designed for precise bending of thin metal wires and grates. This tool delivers the flexibility and control needed for intricate bending operations, allowing us to create custom shapes. Its manual nature makes it ideal for small-batch production and delicate work.

We use the Manual Bending Fixer for metalworking and fabrication, providing our machines with custom components for projects. It’s an ideal for small-scale production and specialized applications.

Powder Coating Department Tanks

Rust removal is a crucial process for preparing metal components. Our Powder Coating Department Tanks are filled with specialized liquids and acids that effectively eliminate rust and other surface impurities. The cleaning process ensures that the powder coating adheres properly, resulting in a durable and appropriate finish.

By effective rust removal, the Powder Coating Department Tanks help us achieve a superior powder coating finish significantly improving the toughness of our metal products.

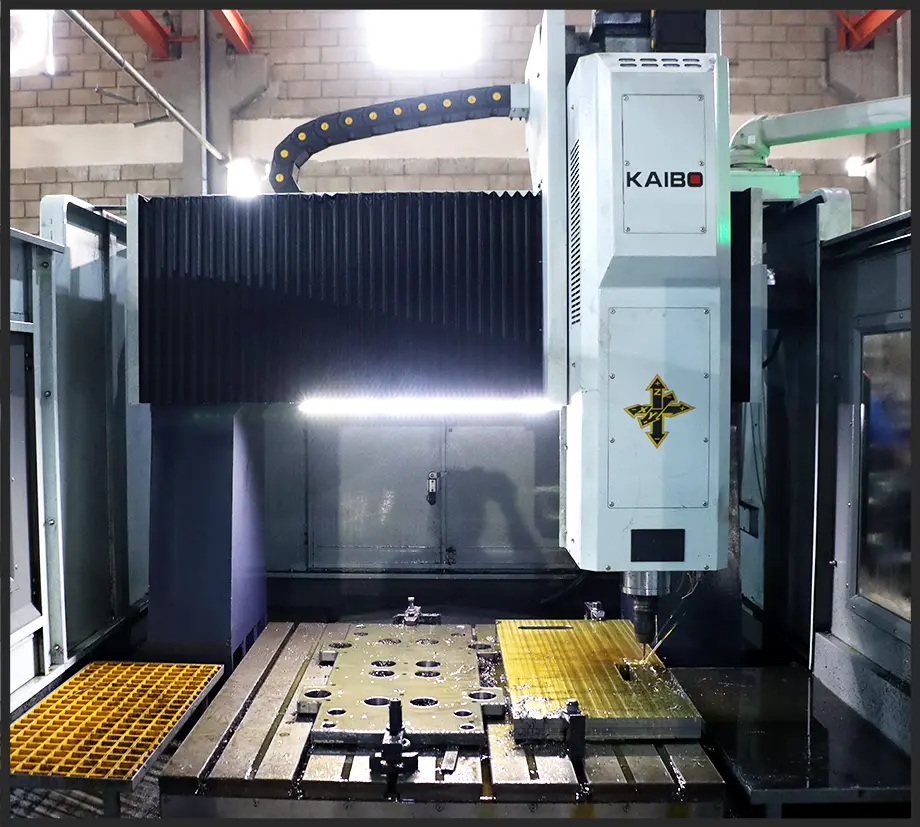

Powder Coating Oven

The Powder Coating Oven provides a controlled environment for curing the powder coat paint, to make sure the finishing is consistent. Its precise temperature and time settings allow us to create a tough coating that bolsters the longevity and appearance of our products.

The Powder Coating Oven produces a thicker and more robust finish than traditional liquid paint while remaining environmentally friendly.

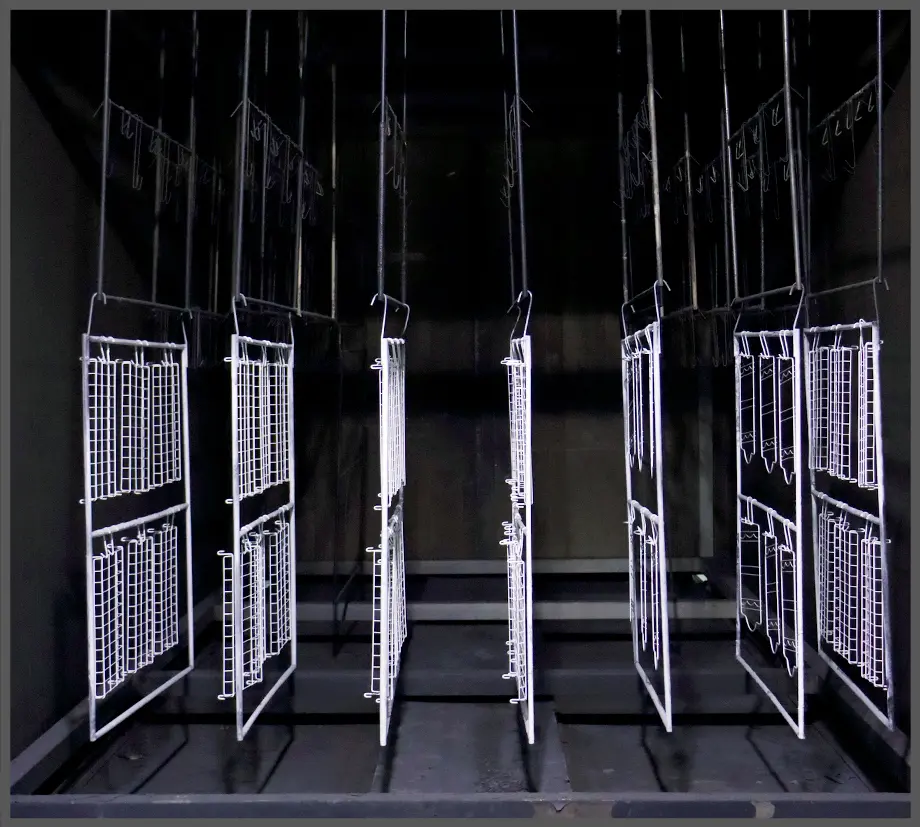

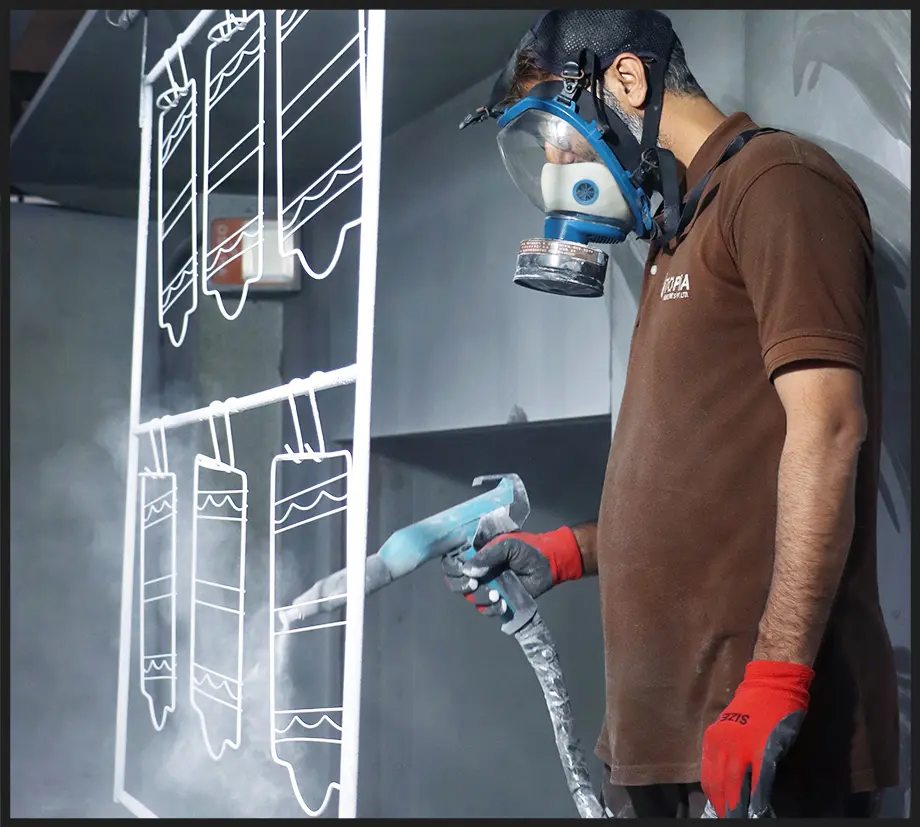

Powder Coating Paint Station

A uniform application of powder coating is essential for yielding top-quality products. Our Powder Coating Paint Station utilizes specialized equipment to electrostatically apply the powder coat, ensuring even coverage. The controlled environment and precise application techniques minimize waste and maximize efficiency.

Through professional powder coating, we ensure that all our products maintain their high-quality appearance and longevity.

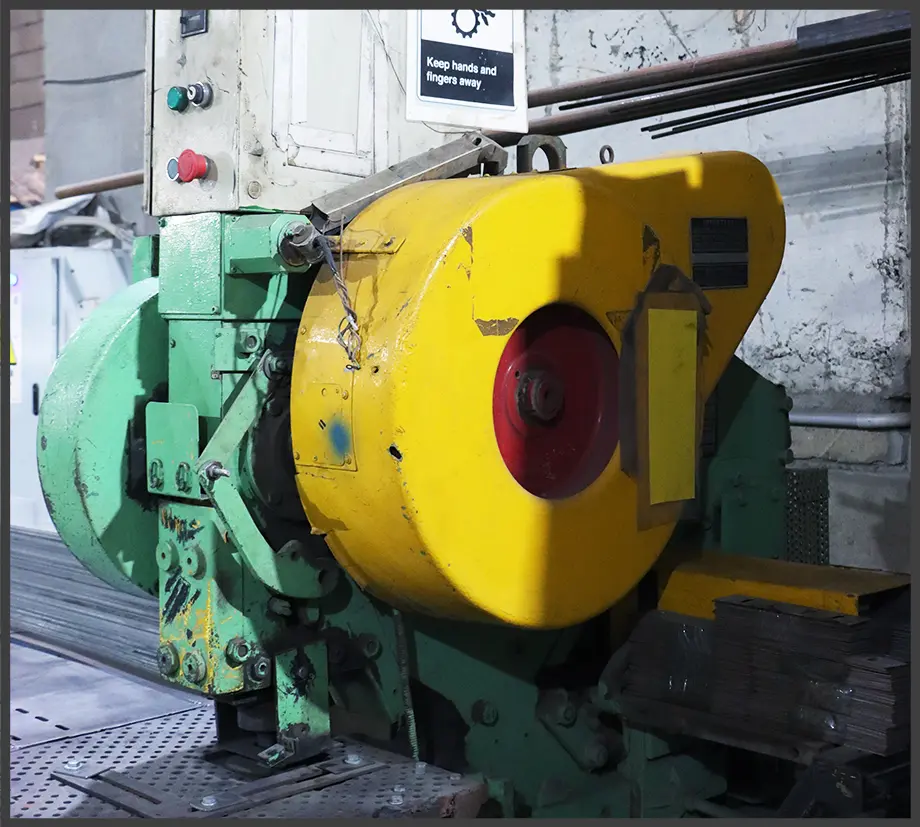

Power Press

The Power Press creates specific capsule-shaped holes in metal sheets. It implements high force and specialized dies to consistently produce these unique hole shapes, essential for specific applications. By ensuring accuracy and consistency, we maintain high standards in our metal fabrication.

This process creates clean and uniform holes and with precise hole-punching, we maintain consistent quality in all our metal components.

Sand Mixer

Thoroughly mixed and prepared sand is vital for the molding process used for casting. Our Sand Mixer produces fine castings with smooth surfaces. This consistent mix minimizes defects and ensures standardized casting quality.

The mixer maintains a precise ratio of sand, binder, and water, providing us with high-quality, and consistently mixed molding sand.

Welding Plant

We are equipped with a state-of-the-art Welding Plant that houses cutting-edge welding equipment for creating strong and reliable welds that are used in high-quality metal structures.

Our Welding Plant is equipped. This plant ensures structural integrity and durability in our products. The plant has a wide range of welding capabilities.

Poly Insert Machine

Our Poly Insert Machine automates the process of inserting pillows into poly bags or covers efficiently and consistently. It positions and inserts pillows, reducing manual labor and increasing production speed.

The Poly Insert Machine ensures uniformity and decreases the risk of errors, leading to streamlined production and completely packaged products.

Surface Grinder

Our Surface Grinder produces exceptionally smooth and specific surfaces on metal components, essential for high-precision parts. It maintains a tight tolerance and flawless finish for the surfaces.

The Surface Grinder is responsible for achieving a very fine surface finish that’s needed for precision metal surface finishing.

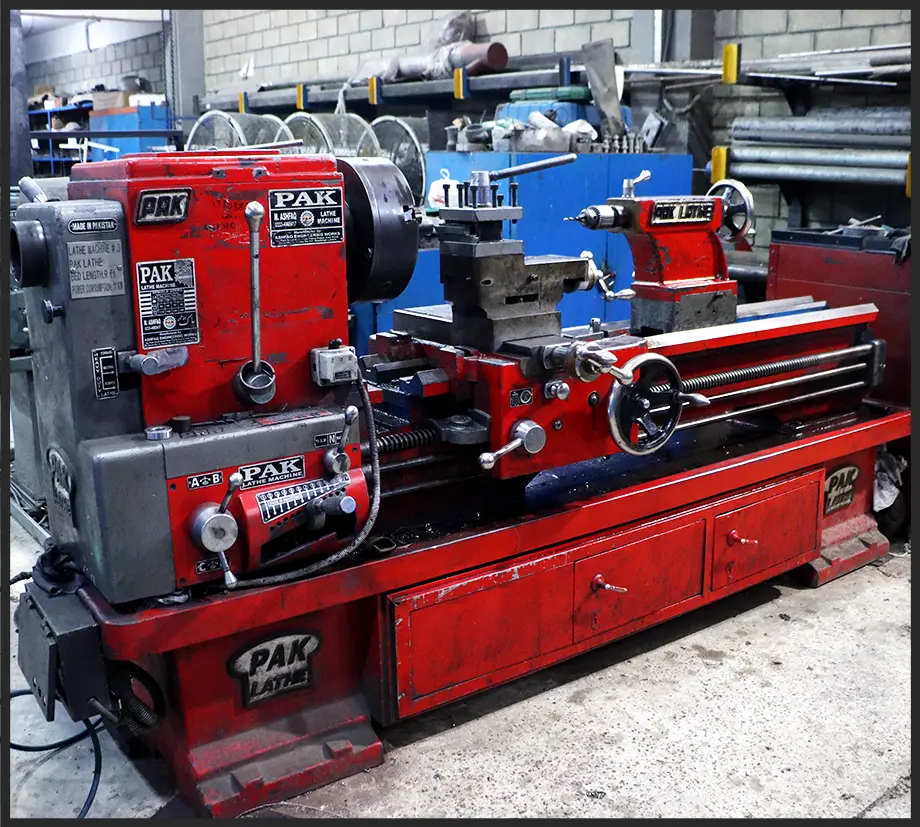

Lathe Machine

Spare parts are essential for maintaining all our machinery. The Lathe Machine is indispensable for manufacturing a wide range of such parts with precision, allowing us to create custom components to replace worn or damaged parts. The production of our own spare parts drastically minimizes downtime and enables continued operation of our production lines.

Producing custom spare parts with exact specifications also keeps our machinery maintained, making the Lathe machine a cost-effective solution for creating highly specialized components.

Piece Bending Fixer

Unlike the Manual Bending Fixer, The Piece Bending Fixer accurately bends small metallic pieces, enabling exact manufacturing of small components. It can be used to repeatedly manufacture identical bent parts.

With the Piece Bending Fixer’s precise bending capabilities and quality small component manufacturing, we ensure efficient production.

Shearing Machine

Metal sheets need to be cut to precise dimensions for the preparation of materials used for further processing. Our Shearing Machine makes meticulous cuts while minimizing waste and maintaining precision consistently.

The shearing machine can handle a variety of metal thicknesses. Other metal fabrication companies can benefit from our shearing machine. We offer shearing services, providing them with precisely cut metal sheets.

Conveyers

The various integrated conveyor systems are a contributing driver for our efficient production processes. The Barcode Scanner Conveyor ensures accurate inventory tracking, while the Roll Unwinder Machine provides consistent fabric feed. In addition, our Coal Loading Conveyor automates fuel delivery, and the Material Shifting Conveyor handles general transport.

All these systems track, feed, and transport materials where needed, optimizing handling and boosting productivity while eliminating human errors, reduce labor costs, and maintaining a smooth material flow.